Product

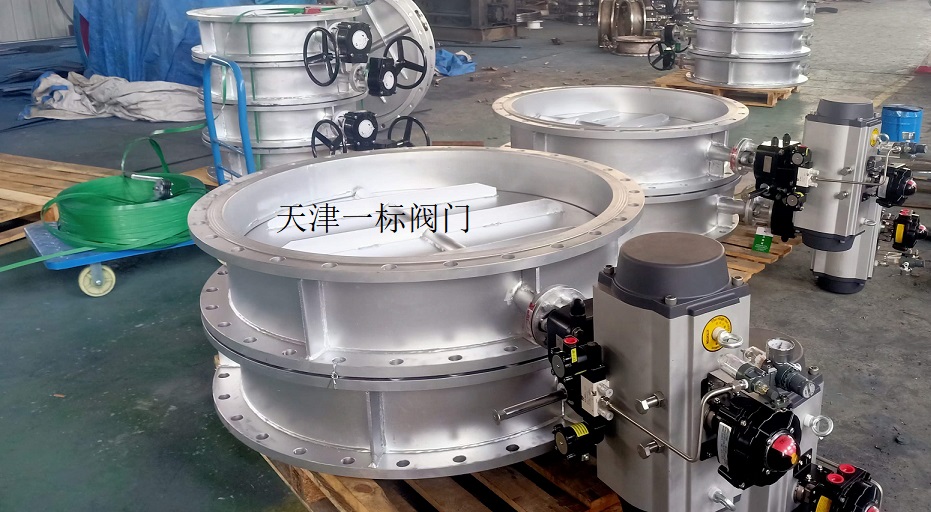

Ultrafiltration inlet pneumatic valve

Brand:Pneumatic eccentric butterfly valve 型号:YD671X-10QRL

超滤进水气动阀门is a key pneumatic drive device used in water treatment ultrafiltration membrane systems to control the entry of raw water or pre treated water into the membrane unit. Its core function is to achieve precise opening and closing or flow regulation of fluids, ensuring stable operation of the system. According to industry applications and technical specifications, its main characteristics and requirements are as follows:1、 Core functions and technical features

Power driven mode

Using compressed air (usually at a pressure of 0.3-0.7MPa) to drive the actuator (cylinder or diaphragm type), the valve can be quickly opened or adjusted, with fast response speed and explosion-proof safety.

The double acting cylinder is suitable for frequent opening and closing scenarios (such as ultrafiltration backwash cycles), while the single acting cylinder (with spring reset) can automatically return to its original position when the gas is cut off, ensuring fault safety.

Valve type and structure

Butterfly valve (clamp type soft seal): Due to its compact structure and low flow resistance (flow resistance coefficient 0.04-0.06), it has become the mainstream choice for ultrafiltration inlet, especially suitable for high flow conditions.

Ball valve: Suitable for high sealing requirements, it can be fully opened and closed by rotating 90 °.

The valve body material should be corrosion-resistant (such as 304/316 stainless steel, ductile iron), and the sealing material commonly used is polytetrafluoroethylene (PTFE) or fluororubber, compatible with water temperature range of -80 ℃ to 180 ℃.

Key performance parameters

Nominal pressure: ≥ 1.0MPa (ultrafiltration working pressure is usually less than 0.8MPa), and a safety margin should be reserved.

Leakage level: In the closed state, it needs to withstand 1.1 times the working pressure without leakage to prevent internal leakage from contaminating the membrane system.

2、 Special requirements and risk control for ultrafiltration systems

Anti leakage design

Leakage inside the valve may cause backwash water containing oxidants (such as sodium hypochlorite) to enter the water production side, oxidizing and damaging the downstream reverse osmosis membrane. Stainless steel valve plates should be used instead of copper materials, and the sealing performance should be regularly tested.

Recommend configuring limit switches to provide real-time feedback on valve position, ensuring accurate switch status.

Attachment configuration optimization

Triple piece (filter pressure reducing valve+oil mist device): Ensure clean air source and prevent impurities from clogging the valve core.

Electrical locator: If flow regulation is required, the opening can be precisely controlled (such as backwash flow grading control).

Speed control valve: Adjust the action speed of the cylinder to avoid water hammer impact on the membrane components.

3、 Typical fault cases and improvement measures

Case: A factory experienced internal leakage due to corrosion of the ultrafiltration inlet valve plate, which led to the infiltration of sodium hypochlorite into the reverse osmosis system, resulting in a decrease in membrane oxidation desalination rate.

Improvement:

Upgrade the valve plate material to stainless steel;

Install residual chlorine online monitoring (control target 1-10 μ g/L), and interlock valve start stop.

【Bace】