Fluorine lined regulating valve

The fluorine lined regulating valve adopts a straight through single seat spherical valve body, which is particularly suitable for working environments with low pressure before and after the valve and strict requirements for leakage. By inputting relevant control signals (4-20mADC or 1-5VDC), the flow rate, pressure, liquid level, temperature, etc. of the regulated medium can be changed to maintain the controlled process parameters at the given values. Electric single seat regulating valves are generally equipped with AOX-L or AOX-Q-L series linear electric actuators, which have the advantages of compact structure, high regulation accuracy, low pressure drop loss, precise flow characteristics, large guiding area, and anti vibration.

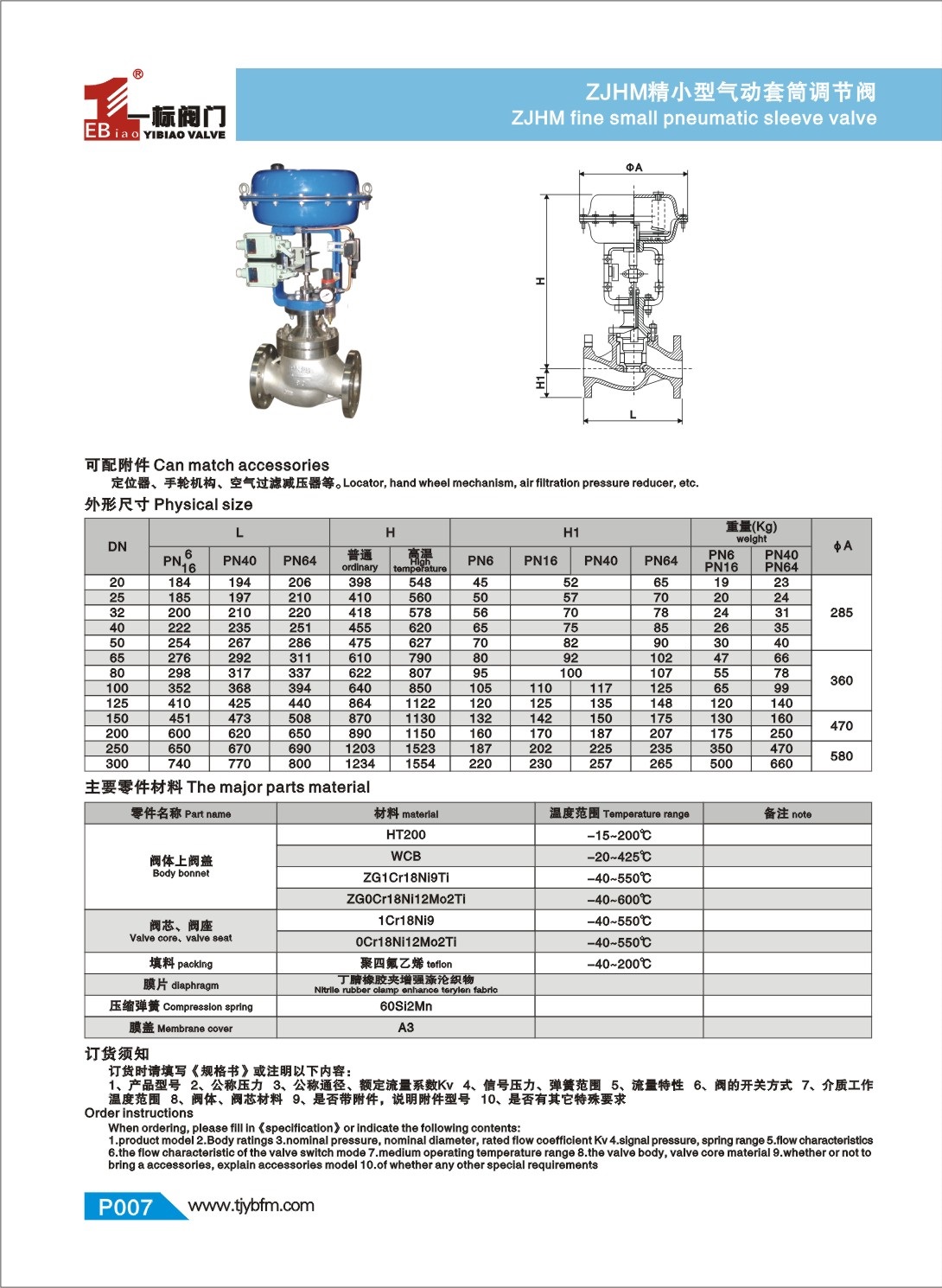

Main parameters of fluorine lined regulating valve

Form: Sleeve guided straight through cage valve

Nominal diameter: DN20 to DN500

Nominal pressure: PN16, 40, 63, 100, ANSI CL150, 300, 600

Valve body and cover materials: WCB, WC6, WC9, CF8, CF8M, HC276, Ti alloy, etc

Valve internal material: 304, 316, HC276, Ti alloy, etc

Packing: PTFE V-shaped, flexible graphite, PTFE packing, flexible graphite with nickel wire

Execution mechanism: pneumatic, electric, hydraulic

Connection with actuator: bolt compression type, round nut locking type

Valve cover types: standard type, high temperature type, low temperature type, bellows type

Connection methods: flange type (RF, MFM, RJ), welding type (SW, BW)

Working temperature: -29 to+230 (standard),+230 to+560 (medium high temperature), -30 to -196 (low temperature, ultra-low temperature)

Leakage level: ANSI B16.104 IV, VI, zero leakage

Flow characteristics: equal percentage, linear, on/off

Inherent adjustable ratio: 50:1