Marine pneumatic valve

Comprehensive information of marine pneumatic valves:

1. Core standards and types

GB/T 5744-2023: The current national standard for marine pneumatic quick closing valves is applicable to fuel and lubricating oil pipeline systems, with a nominal pressure extended to 4.0MPa, new water medium compatibility, and optimized anti jamming design for straight through structures.

Main types:

Quick closing valve: complete emergency cut-off within 0.5 seconds, equipped with compressed air drive and ESD (emergency stop) function.

Pressure reducing valve: such as Y42XF16 diaphragm type, used to regulate pipeline pressure (DN50 and other specifications) ^ ^.

2. Typical products and parameters

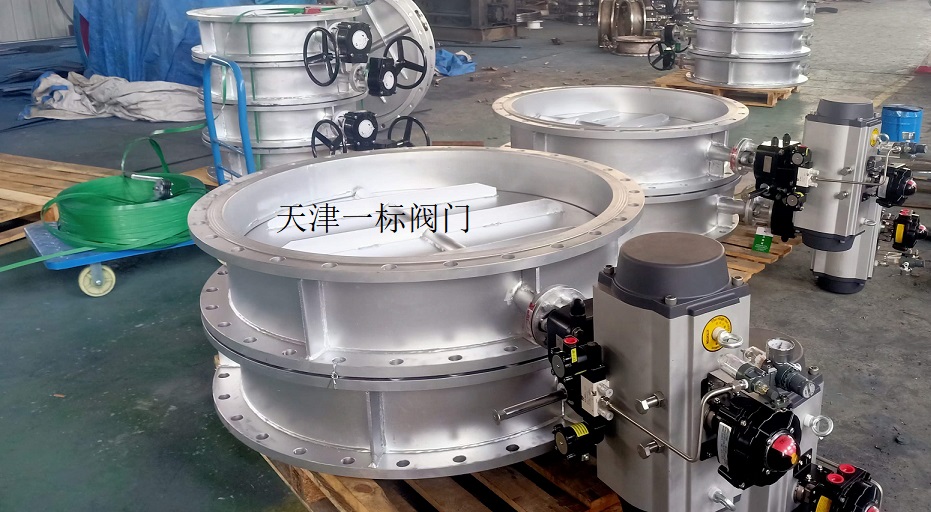

One standard ship pneumatic quick closing valve GB/T5744 cast steel quick closing valve quick closing valve DN20

180 day return and exchange policy, damaged package return and exchange policy, 7-day no reason return policy, 7-day price guarantee, free on-site return and exchange policy, lightning refund policy, fast review policy, late delivery compensation policy

Emergency cut-off of straight through diesel pipeline GBT5744-93 DN20 (AQ type) with flange cast steel pneumatic quick closing valve for first-class ships

Support 7-day no reason return and free on-site return and exchange

T standard ship valve, ship manual quick closing valve, fuel quick closing valve, ship pneumatic quick closing valve, ship pneumatic quick closing valve, manual L=150/4 holes/center distance 68

Fast review, late arrival compensation, 180 day replacement without repair, damaged package return and exchange, 7-day no reason return support, free on-site return and exchange, lightning refund

3. Application scenarios and technical requirements

Safety system: The rapid isolation of the main steam pipeline and fuel delivery requires certification from classification societies such as CCS/ABS.

Adaptation to harsh environments:

Salt spray corrosion resistance (such as bronze material with no corrosion after 720 hours of testing).

Explosion proof design (ExdI explosion-proof rating) and anti-static treatment.

4. Selection suggestions

Priority criteria: Select products that comply with GB/T 5744-2023 to ensure emergency cut-off response speed and sealing performance.

Special requirements:

High temperature media (such as steam) require the use of chromium molybdenum steel valve bodies.

LNG scenarios require low-temperature sealing materials (-162 ℃ working condition).