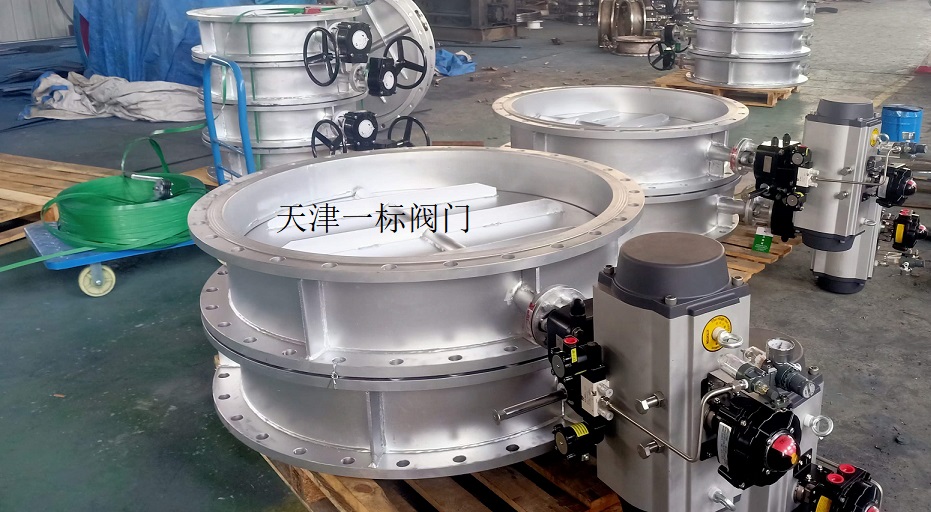

Electric ash unloading ball valve _ Pneumatic ash unloading ball valve

The following is a comparative analysis of electric ash discharge ball valves and pneumatic ash discharge ball valves, with comprehensive technical parameters, application scenarios, and market data:

1. Comparison of core functions

Features: Electric ash discharge ball valve, pneumatic ash discharge ball valve

Drive mode: motor drive (supports remote/programmable control), compressed air drive (fast response speed)

Applicable media include coal powder, lime, high dust containing fluids with particles, and high-temperature gases (such as coal powder injection)

Sealed design with hard seal (V-shaped sphere, wear-resistant) and double valve stem structure (anti dust accumulation and blockage)

Control accuracy adjustable opening (some models) switch type main (quick opening and closing)

2. Technical parameters

Electric ash discharge ball valve

Pressure range: 1.6-4.0 MPa (high-pressure models can reach up to 10.0 MPa)

Temperature range: -20 ℃~+450 ℃ (higher for special materials)

Diameter range: DN50~DN500

Typical model: Q947MF (carbon steel flange connection)

Pneumatic ash unloading ball valve

Pressure range: 0.1-1.6 MPa (normal to medium pressure)

Temperature range: -30 ℃~+200 ℃ (special design required for high temperature)

Diameter range: DN15~DN300

Typical model: Q647MF (pneumatic actuator)

3. Application scenarios

Electric type:

Metallurgical industry blast furnace coal powder injection system (precise flow control required)

Power plant ash discharge pipeline (long-term stable operation)

Pneumatic type:

Chemical dust transportation (quick opening and closing explosion-proof)

Cement plant unloading system (wear-resistant design)

选型建议