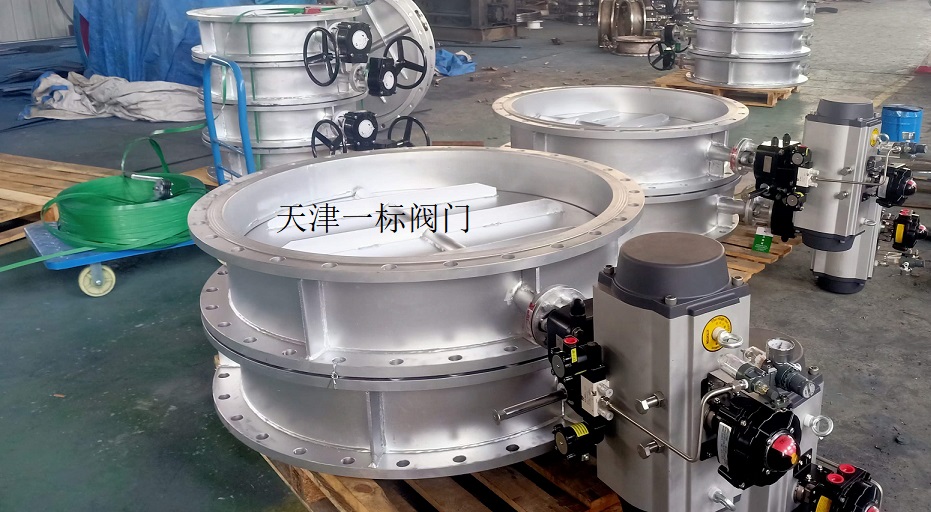

Product

Fully lined fluorine pneumatic butterfly valve

Brand:Pneumatic eccentric butterfly valve 型号:YD671F-10F

对夹全衬氟气动蝶阀is an industrial valve designed specifically for highly corrosive media. Its core feature is the overall lining of fluoroplastics (such as PTFE, FEP, etc.) on the inner cavity of the valve body and the surface of the butterfly plate, combined with pneumatic actuators to achieve automated control. Its main characteristics and applications are as follows: 一、核心结构与工作原理1、 Core structure and working principle

一、核心结构与工作原理1、 Core structure and working principleFully lined fluorine design

The valve body, butterfly plate and other overcurrent components are lined with integral fluoroplastics (such as PTFE, F46) to completely isolate the medium from the metal substrate.

Applicable media include sulfuric acid, hydrochloric acid, hydrofluoric acid, aqua regia, strong alkali, and organic solvents, and can withstand extreme corrosive environments with pH values ranging from 1 to 14.

Pneumatic drive mechanism

By driving the valve stem with a pneumatic actuator (piston or diaphragm), the butterfly plate is rotated 90 ° to achieve rapid opening and closing (response time of 0.5-2 seconds).

Support remote control, configurable locators and solenoid valves to achieve precise flow regulation or emergency shut-off.

2、 Key performance advantages

Excellent corrosion resistance

Fluoroplastic layer (thickness ≥ 2.5mm) provides comprehensive anti-corrosion protection, with a lifespan of up to 5-10 years, far exceeding metal valves.

Zero leakage seal

Four level sealing structure: butterfly radial seal+axial compression+valve stem packing+flange gasket, in compliance with ANSI B16.104 Level VI standard.

Bidirectional bubble level seal, suitable for forward and reverse pressure.

Low resistance and high efficiency

Streamlined flow channel design, low flow resistance coefficient (high Cv value), and pressure drop only one-third of the same diameter valve.

The operating torque is 60% lower than that of ball valves, and energy consumption is reduced by 40%.

Wide working condition adaptability

Temperature range: -50 ℃~180 ℃ (special design can be extended to -196 ℃).

Pressure rating: PN10-PN16 (Class150~300).

3、 Technical parameters (mainstream standards by 2025)

Project parameter range remarks

The advantage of large diameter is obvious for nominal diameter DN50~DN1200

The nominal pressure PN10~PN16 corresponds to Class150~300

Applicable temperature -50 ℃~150 ℃ (standard) High temperature type up to 180 ℃

Leakage level ANSI VI (zero leakage) hard seal structure

Flow characteristics are approximately linearly adjusted with an opening of 0 °~90 ° for precise flow control

开度0°~90°精准控流

4、 Application scenarios

Chemical industry: transporting highly corrosive media such as sulfuric acid, hydrochloric acid, aqua regia, etc.

Pharmaceutical/Food: Meet the requirements of pollution-free and high cleanliness, and comply with hygiene standards.

Environmental protection engineering: corrosion protection for sewage treatment and exhaust gas discharge systems.

Special working conditions: explosion-proof environment (such as oil platforms), low-temperature LNG pipelines.

5、 Selection and installation points

Selection criteria: Select the lining material (PTFE/FEP) and actuator type based on the corrosiveness of the medium, temperature and pressure, and flow accuracy.

Installation specifications: Priority should be given to horizontal installation to avoid mechanical damage to the lining; The pipeline needs to be cleaned to prevent impurities from jamming.

【Bace】