Product

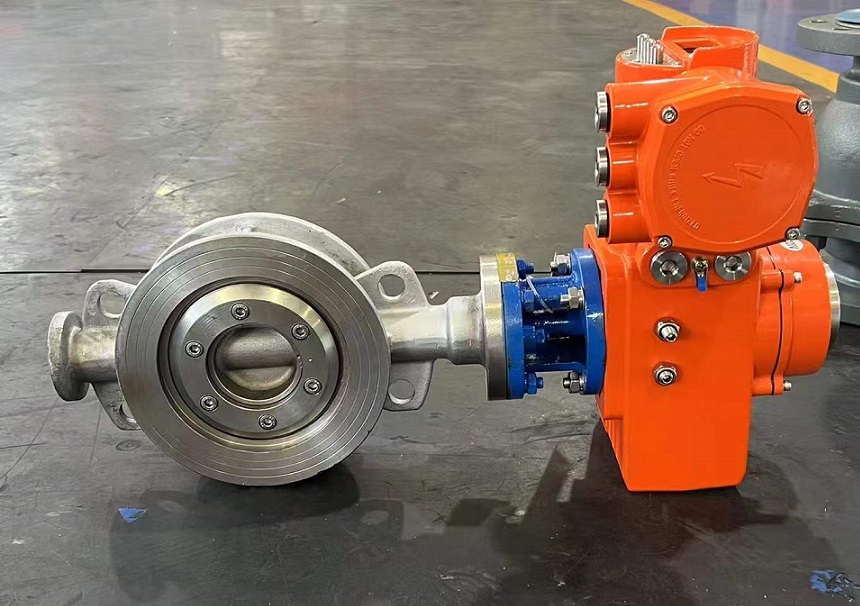

Explosion proof electric hard sealed butterfly valve

Brand:Pneumatic eccentric butterfly valve 型号:FD973H-16P

防爆电动硬密封蝶阀Specially designed for flammable and explosive environments, it integrates explosion-proof, hard sealing, and electric control, combining safety and high performance. Its main technical features and applications are as follows:1、 Core Structure and Technical Characteristics

Explosion proof design

The executing agency has passed Exd Ⅱ BT4/IP67 or above explosion-proof certification and is suitable for industrial environments containing explosive gases (such as petrochemicals and coal mines).

Adopting a fully enclosed induction motor and mechanical clutch mechanism, supporting remote automation control to avoid on-site operational risks.

Hard sealing structure

Triple eccentric metal seal: The butterfly plate and valve seat are welded with stainless steel/cobalt based alloy, which can withstand high temperature and high pressure from -40 ℃ to+425 ℃ (PN1.6-PN6.4), achieving bidirectional zero leakage (leakage level up to VI).

Wear resistance: The multi-layer metal sealing ring is resistant to particle erosion and has a lifespan 5 times longer than soft seals. It is suitable for media such as dusty coal gas and flue gas.

Electric execution performance

The power supply supports AC220V/380V or DC24V, with an input signal of 4-20mA for precise flow regulation.

Torque range of 50N · M~3000N · M, short opening and closing time at 90 °, with overload protection and mechanical self-locking function.

Energy industry: Power plant boiler steam pipeline (pressure resistance ≥ 10MPa), LNG ultra-low temperature (-162 ℃) storage and transportation system.

Petrochemical safety: crude oil transportation, catalytic cracking units (resistant to sulfur corrosion), chemical acid and alkali pipelines (compatible with Hastelloy valve bodies).

High risk media: gas and natural gas pipeline cut-off, metallurgical high-temperature flue gas regulation.

Environmental protection system: flow control of sewage treatment, ventilation and dust removal pipelines.

3、 Mainstream models and selection parameters

Model Example Connection Method Nominal Diameter Pressure Rating Applicable Scenarios

D973H-16P clamp type DN50-DN450 PN1.6 gas/dusty gas pipeline

D943H-16C flange type DN50-DN2000 PN1.6-PN2.5 large-diameter high-temperature fluid (such as steam)

FD943H flange DN400+PN2.5 petrochemical explosion-proof high-risk area

选型注意:Selection precautions:

Low temperature working conditions require the specification of low-temperature steel valve bodies (such as 316L) and nickel based seals.

Alloy coating (such as C-276 Hastelloy) should be selected as the corrosive medium.

Valves with a diameter of DN1000 or above need to strengthen their structural design and control the diameter error to be ≤ ± 0.5mm.

DN1000以上大口径阀门需强化结构设计,控制通径误差≤±0.5mm。

【Bace】