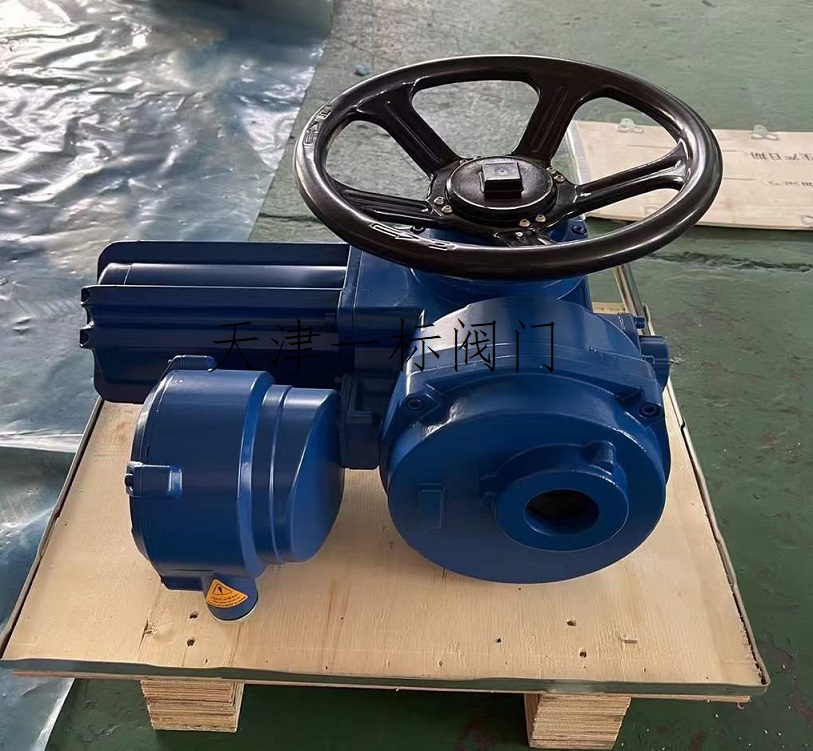

High voltage electric butterfly valve

Pressure level

Work pressure range: PN16-PN100 (some imported models up to PN160/ANSI 900)

Valve body material: forged carbon steel, stainless steel (304/316) or alloy steel, with high compressive strength

Sealing performance

Metal hard seal (such as Stellite alloy overlay welding), temperature resistance up to 600 ℃, leakage level ANSI Class VI

Triple eccentric design, zero friction opening and closing, with a lifespan of over 100000 cycles

Drive and Control

The electric actuator supports 4-20mA signal or PROFIBUS communication, with a positioning accuracy of ± 0.5%

Explosion proof model certified by ATEX/Exd Ⅱ BT4, suitable for hazardous environments

2、 Typical application scenarios

Energy industry: Main steam pipeline of thermal power plants (pressure resistant PN100, temperature resistant 600 ℃)

Petrochemical industry: High pressure oil and gas transportation (anti-static design, PN64 explosion-proof type)

Metallurgical industry: blast furnace gas pipeline (wear-resistant hard seal, containing granular media)

3、 Selection suggestions

High pressure condition (PN ≥ 64): Priority should be given to imported brands such as Flowserve from the United States or B ü rkert from Germany, and the valve body needs to be forged

Corrosion environment: Dual phase steel valve body+PTFE lining (such as KITZ in Japan), resistant to chloride ion corrosion

Intelligent control: Italy OMAL supports IoT remote monitoring and adapts to smart water management systems

4、 Maintenance points

Sealing test: Monthly pressure holding test (1.1 times working pressure), leakage rate must comply with GB/T 13927

Lubrication cycle: Add molybdenum disulfide grease to the valve stem every quarter, and change the oil in the worm gear box every 2000 hours