Tank area valve

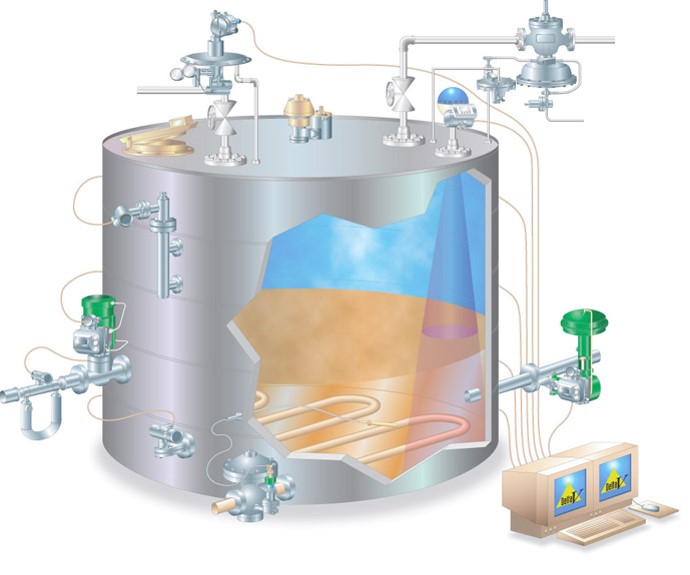

The following is a comprehensive information compilation about tank area valves, combined with the types, functions, and layout requirements of tank valves:

1、 Types and functions of valves in tank farms

Can root valve

The first valve located in the inlet and outlet pipelines of the storage tank is used for physical isolation in non emergency situations (such as maintenance) and needs to be kept open for a long time. Mechanical gate valves are preferred to ensure stability.

Emergency shut-off valve

Quickly cut off materials during interlocking alarm to prevent the accident from escalating. The following scenarios must be met:

Import and export pipelines for liquefied hydrocarbon storage tanks and large atmospheric storage tanks (≥ 30m or ≥ 10000m3);

Major hazard source storage tanks (such as toxic gases, flammable liquids).

Breathing valve/flame arrester

Used for tank pressure balance, such as 304 stainless steel flame retardant breathing valve (corrosion-resistant, suitable for oil tanks).

2、 Valve layout sequence and specifications

Typical Layout Process

Tank flange → metal hose (compensating for settlement) → tank root valve (mechanical isolation) → emergency shut-off valve (interlock protection).

Precautions

The emergency cut-off valve needs to be interlocked with the liquid level alarm (high high liquid level closes the feed valve, low low liquid level cuts off the discharge);

Metal hoses must comply with the flexible connection requirements of GB 50160-2018, but it may reduce the strength of the pipeline.

选型建议