Product

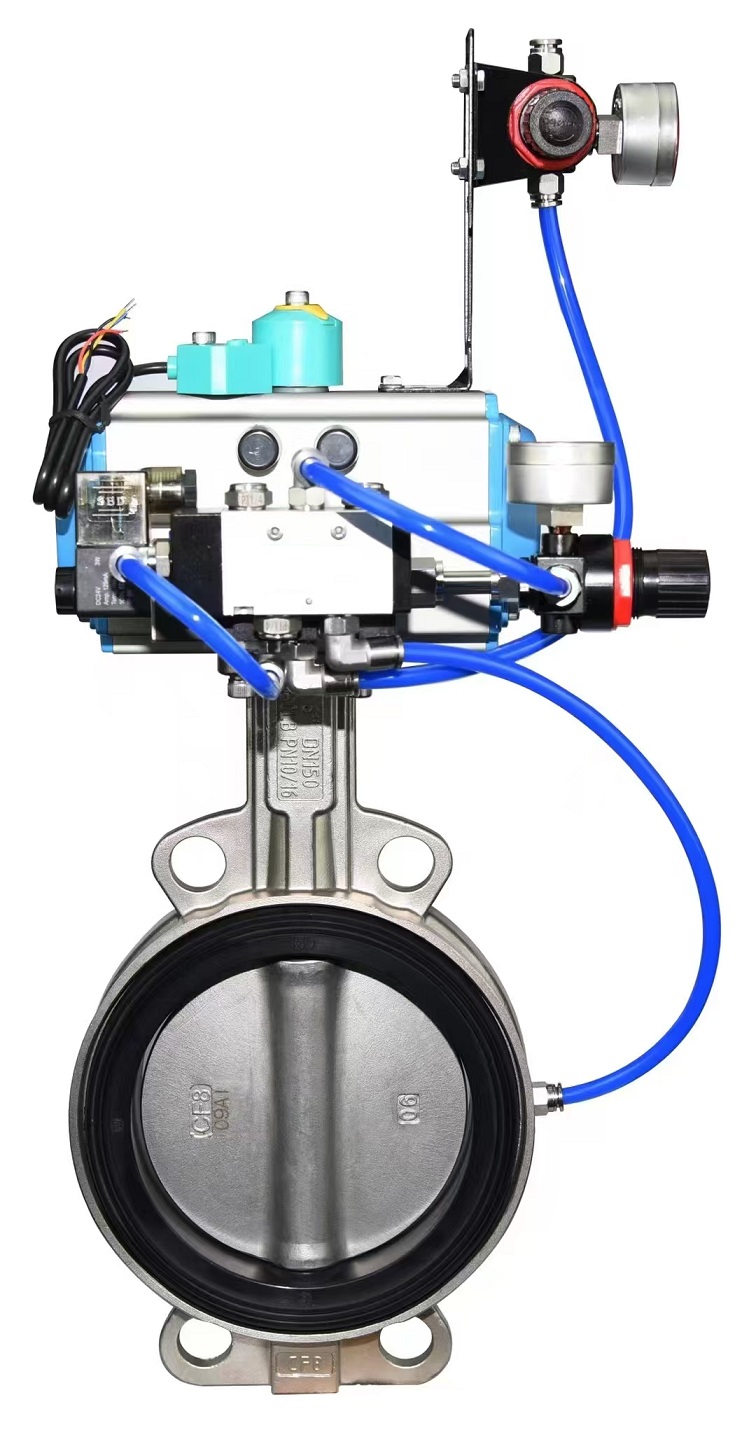

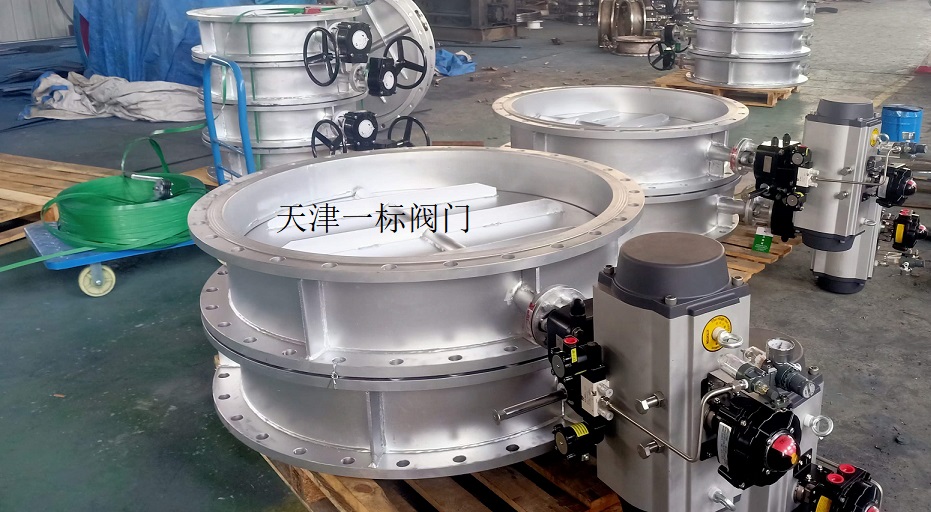

Expansion type pneumatic butterfly valve

Brand:Pneumatic eccentric butterfly valve 型号:PZD671X

Technical Analysis of Expansion Pneumatic Butterfly Valve

1、 Core Features

Sealing principle

Adopting an inflatable expansion valve seat design, the sealing ring is radially expanded by injecting compressed air through a pneumatic actuator, achieving a tight fit with the butterfly plate. It is suitable for zero leakage control of complex media such as particles and powders.

Drive mode

Standard single or double acting pneumatic actuators, supporting 5-7 bar air source pressure, optional accessories such as solenoid valves and positioners, to meet automation control requirements.

Emergency design

Configure a manual operation device that can quickly switch to manual mode in case of gas source failure, ensuring system continuity.

2、 Structural Design

Key configuration of components

Valve body material: ductile iron, 304/316 stainless steel (corrosion resistance improved by more than 50%)

Sealing materials EPDM (aging resistant), PTFE (acid and alkali resistant), metal hard seal (high temperature resistance up to 200 ℃)

Connection forms include clamp type (accounting for 80% of application scenarios) and flange type, suitable for DN40-DN2000 pipelines

Dual cylinder redundant design for actuator (reducing failure rate by 60%), optional explosion-proof certification (Ex ib IIC T4)

3、 Technical parameters

Pressure rating: PN10/16, CLASS 150LB, maximum tolerance 1.6MPa

Temperature range: -30 ℃~150 ℃ (EPDM seal), metal seal can be extended to 200 ℃

Leakage level: VI level (soft seal), IV level (hard seal) 813

Flow efficiency: When fully open, the flow resistance coefficient is ≤ 0.3, and the flow loss is reduced by 40% compared to ordinary butterfly valves

4、 Typical applications

Powder conveying

The cutting control of granular media such as Portland cement and PVC powder improves the wear resistance by three times compared to ordinary butterfly valves.

Environmental Protection Engineering

Dynamic regulation of dust airflow in exhaust gas treatment systems, adapted to environments containing corrosive gases such as SO ₂.

Food and Medicine

Material transportation under sanitary conditions, with the inner wall of the valve body polished to Ra ≤ 0.8 μ m, in compliance with FDA standards.

5、 Key selection points

Adaptation to working conditions

Corrosive medium: 316L valve body+PTFE valve seat 13 is preferred;

High temperature scenario: hard seal+water-cooled jacket design (temperature tolerance increased to 400 ℃).

Control requirements

Matching locator (adjustment accuracy ± 1%) and limit switch (position feedback error ≤ 0.5 °) is required.

Installation specifications

For clamp type valves, sufficient bolt pre tightening space should be reserved to avoid uneven stress on the sealing ring leading to leakage.

Note: When selecting, parameters such as medium particle size (recommended ≤ 5mm) and gas source stability (fluctuation range ± 0.2bar) should be clearly defined to avoid seal failure due to exceeding the limit.

【Bace】