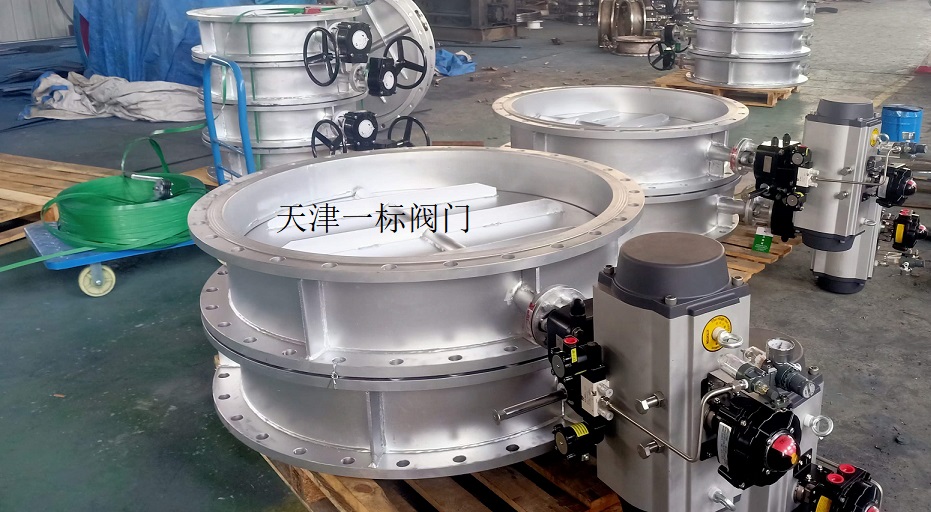

Product

Pneumatic fluorine lined ball valve

Brand:Pneumatic eccentric butterfly valve 型号:Q641F-16F

Detailed analysis of pneumatic fluorine lined ball valve:

1、 Product definition and core functions

Pneumatic fluorine lined ball valve is a corrosion-resistant valve that drives the ball to rotate through a pneumatic actuator, specifically designed for regulating or cutting off corrosive media such as strong acids and alkalis.

Its core features include:

Full lined fluorine structure: The valve body cavity and sphere are lined with fluoroplastics such as perfluoroalkoxy (F46) and PTFE, which have extremely strong corrosion resistance.

High sealing performance: Bubble level sealing (leakage ≤ 0.01 × DN mm3/s) is achieved through V-shaped PTFE packing and compression sealing technology.

Explosion proof design: An anti-static device is installed between the valve stem and valve body, suitable for flammable and explosive environments.

2、 Technical parameters and structure

Parameter specification range remarks

Nominal diameter DN15~DN300 (partially supports DN400) flange/thread/clamp type connection

Pressure rating PN1.0~4.0MPa (ANSI 150~300LB) High pressure models require customization

Suitable for temperatures ranging from -40 ℃ to+180 ℃. Special treatment type can reach temperatures up to -50 ℃ to+200 ℃

Drive mode: Single/double acting pneumatic actuator can be equipped with a locator to achieve 4-20mA adjustment

Key structure:

Floating ball design: The ball and valve stem are integrated to avoid detachment caused by pressure changes.

Execution mechanism: GT/AT series piston type, output torque 32~3000N · m.

3、 Typical application scenarios

Chemical industry: pipeline control for highly corrosive media such as sulfuric acid and hydrofluoric acid.

Pharmaceutical field: Delivery of acid-base solutions in sterile environments.

Environmental engineering: Corrosive wastewater treatment system containing solid waste.

选型建议

【Bace】