pneumatic valve

The following is a comprehensive information summary about pneumatic valves, combined with their working principles, classifications, applications, and procurement points:

1、 Definition and Working Principle

Pneumatic valve is a fluid control device that uses compressed air to drive actuators such as pistons and cylinders to open, close, or regulate valves. The core principle is that compressed air drives the piston to move, and the force is transmitted to the valve core through the curved arm or crossbeam, changing the medium's on/off or flow rate. A typical configuration includes two five way solenoid valves (controlling double acting cylinders) and an intelligent display instrument (monitoring valve position status).

2、 Main types and characteristics

Pneumatic control valve

Used for adjusting parameters such as flow rate and pressure, supporting proportional control (such as V-shaped valve core), with fast response speed and intrinsic safety.

There are two types of structures: straight stroke (such as single seat valves) and angular stroke (such as ball valves and butterfly valves).

Pneumatic gate valve/ball valve

Gate valves rely on medium pressure for self sealing or external force for forced sealing, suitable for fully open and fully closed scenarios.

The ball valve rotates 90 ° to achieve opening and closing, with low fluid resistance and reliable sealing (such as a threaded ball valve).

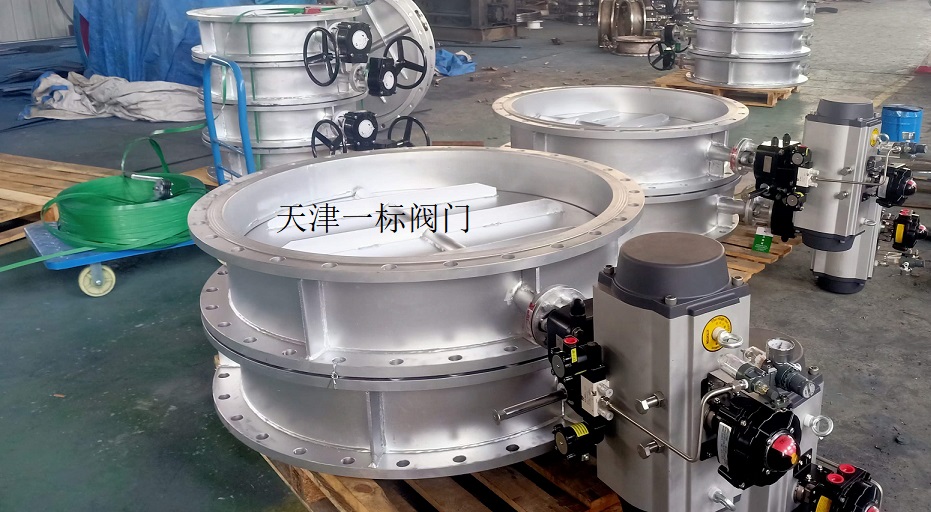

Pneumatic butterfly valve

The midline soft seal type (such as D671X-16Q) is suitable for sewage treatment, while the hard seal type is heat-resistant (such as flue butterfly valves).

选型建议