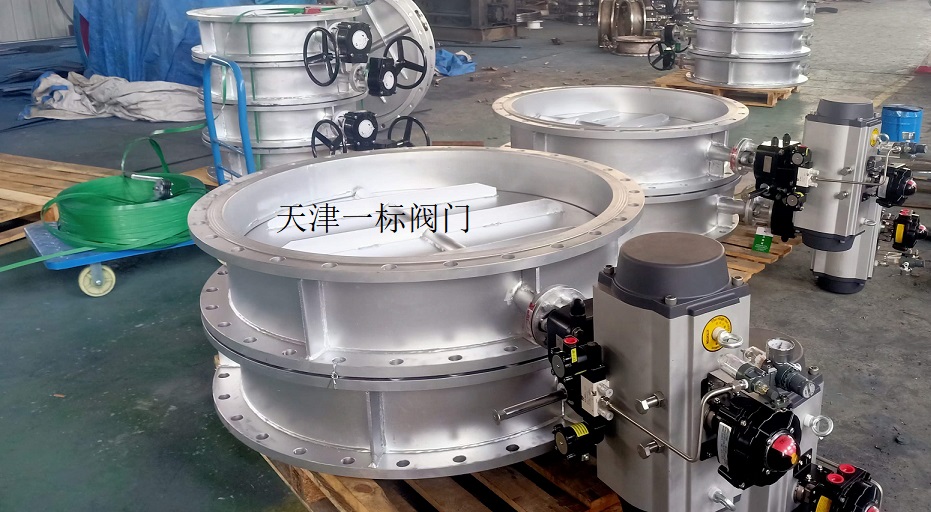

Product

Pneumatic valve modification

Brand:Pneumatic eccentric butterfly valve 型号:VQ647F,VQ647H

以下是气动阀门改装的核心步骤与关键技术要点,整合工业及民用场景实操经验:

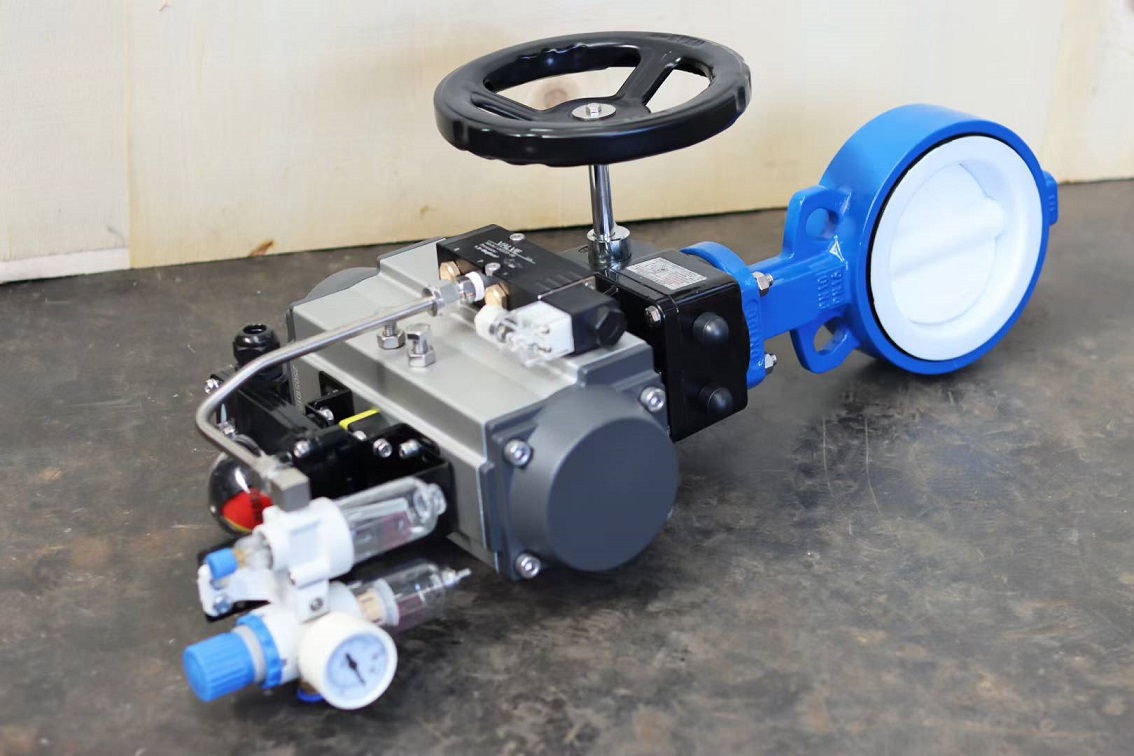

1、 Installation of actuators and mechanical modificationDismantle manual components

Remove the manual handle of the original valve and expose the square hole (or hexagonal structure) at the top of the valve stem.

Measure the size of the valve stem, select the corresponding pneumatic actuator, and convert the interface difference through a variable diameter sleeve.

Rotate the valve to the fully open/fully closed position, install the cylinder at the corresponding position, and ensure synchronous travel.

Welding reinforcement of key parts (such as cutting the original shaft when the shaft diameter is insufficient, and welding the thickened shaft body and blades after enlarging the hole).

Gas path integration

Connect the solenoid valve to control the air source, use a pressure resistant air pipe, and test whether the cylinder's push-pull stroke is smooth.

2、 Control logic and functional optimization

Power off protection mode

Disassemble the valve body to adjust the position of the valve core, and after reassembly, achieve automatic shut-off/opening of the valve.

Video demonstration:

Dual control backup design

Retain the manual pull rod mechanism, and install the pneumatic push rod through an independent bracket, which can quickly switch to manual operation in case of malfunction.

Intelligent linkage upgrade

Install water immersion sensors or PLC systems to achieve automatic valve closure and remote mobile control for leaks.

3、 Debugging and Fault Prevention

Sealing verification

Conduct a 1.1 times nominal pressure test, inspect the flange sealing surface and packing box, and maintain pressure for 5 minutes without any leakage.

Accurate calibration of itinerary

Opening adjustment: Rotate the limit screw (A) to control the opening angle of the valve, ensuring that the valve plate is perpendicular to the pipeline.

Close tightness: Adjust the limit screw (B) and test the spring preload force (reserve 2-3mm gap to prevent jamming).

Common fault handling

Solution to Fault Phenomena

Valve blockage, clean valve core impurities, replace worn bushings

Install a filter to stabilize the pressure fluctuation of the gas source to 0.4-0.7MPa

Uniformly tighten the cover bolts (18-22N · m) for external leakage

4、 Special scenario applications

Automotive exhaust modification: Retain the original vehicle interface and install a vacuum assisted pneumatic valve to achieve graded sound control and avoid carbon deposition.

Sprinkler valve: Stainless steel pneumatic ball valve is selected, which is corrosion-resistant and supports long-term operation.

Tip: When dealing with explosion-proof environments or large-diameter valves, it is recommended to use original actuators and strictly follow the gas source purification specifications (moisture content ≤ 0.01%).

【Bace】