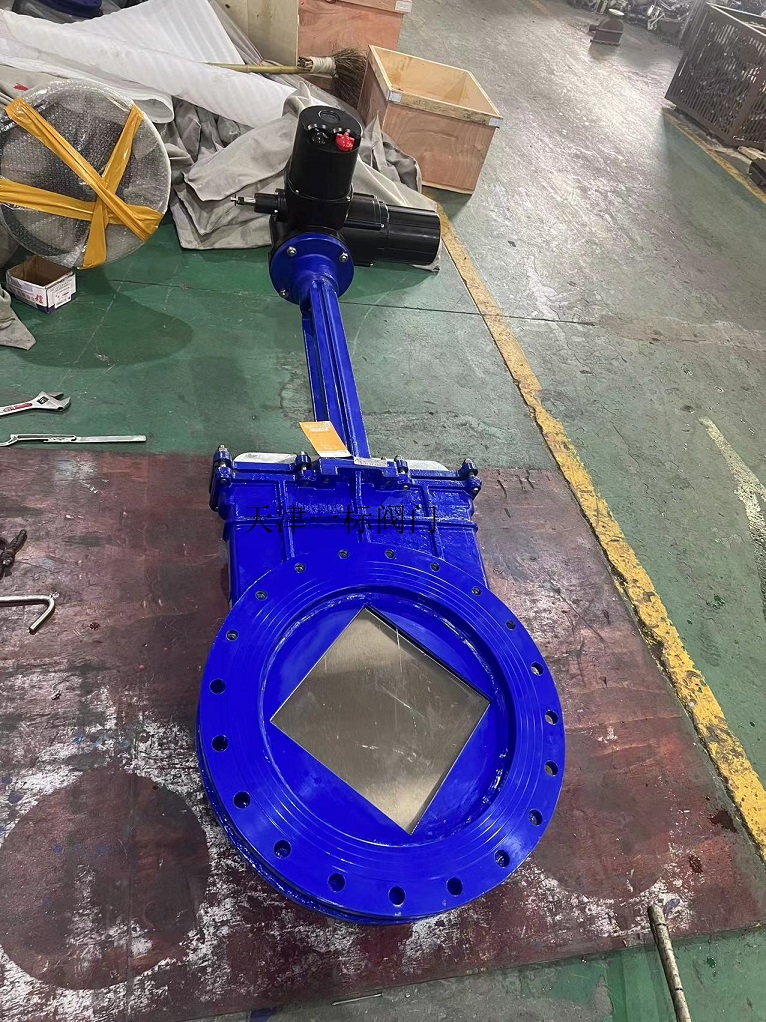

Pneumatic piston cut-off valve

Working principle of pneumatic piston cut-off valve

When the signal pressure is zero, the valve core is in its initial state (normally open or normally closed) due to the preload force of the spring (single acting only). When the actuator receives a signal pressure (0.4~0.6MPa), the compression spring drives the push rod, valve body, and valve core to move to the limited position, making the valve fully open or fully closed. To achieve control over the connection, disconnection, or switching between pipelines for the medium inside the pipeline. Equipped with a two position three-way electric sample valve, the piston type cut-off valve control is more convenient and simple.

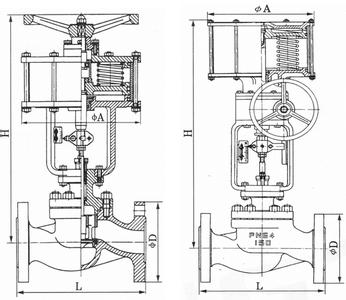

Structural principle of pneumatic piston cut-off valve

The pneumatic piston cut-off valve consists of two parts: a pneumatic piston actuator and a straight stroke adjustment mechanism, which are connected by a bracket edge in the middle. According to the form of the regulating mechanism, pneumatic piston cut-off valves can be divided into three types: straight through single seat cut-off valves (ZSQP type), straight through sleeve cut-off valves (ZSQM type), and two position three-way cut-off valves (ZSQN type). There are two types of pneumatic piston actuators: single acting (spring reset) and double acting (double intake). Adopting a single acting actuator, the overall operation mode of the machine can be divided into air closed (horizontal pipeline connection) and air open (horizontal pipeline disconnection). Pneumatic piston cut-off valves have two sealing forms: hard seal and soft seal, which are suitable for different temperatures and pressures. The ZSQM pneumatic piston sleeve cut-off valve adopts a balanced valve core, which can increase the cut-off pressure difference. The two position three-way cut-off valve adopts a four-way valve body with three flow ports, which is particularly suitable for switching between two flow paths.

Main component materials

| ZSQ活塞式气动切断阀阀体、阀盖 | ZSQ活塞式切断阀阀芯 | ZSQ气动切断阀阀座 | 气缸体 | 活塞 | 填料 | 阀芯软质密封件 |

| HT200、ZG230-450、 ZG1Cr18Ni9Ti、ZGOCr18Ni12Mo2Ti | 1Cr18Ni9Ti、 Cr18Ni12Mo2Ti | 1Cr18Ni9Ti、 Cr18Ni12Mo2Ti | ZG230-450 | ZAlSi12 | 聚四氟乙烯,柔性石墨 | 增强聚四氟乙烯 |

气动活塞切断阀主要技术参数

| ZSQ型气动切断阀公称通径 DN ( mm ) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | ||

| 额定流量系数( KV ) | 7 | 11 | 20 | 30 | 48 | 75 | 120 | 190 | ||

| 额定行程( mm ) | 8 | 12 | 20 | 25 | ||||||

| 气缸直径( mm ) | 75 | 100 | 150 | |||||||

| 允许泄 >漏 量 | 硬密封( l/h ) |

单座、三通: 1.2 × 10 -7 ×阀额定容量 套筒: 5 × 10 -6 ×阀额定容量 |

||||||||

| 软密封 | VI 级 | |||||||||

| 工作温度() | -20~200 -40~450 | |||||||||

| 公称压力 PN ( MPa ) | 1.6 4.0 6.4 | |||||||||

| 允许压差 >( MPa ) | ZSQP | 单作用 | 1.16 | 0.66 | 0.39 | 0.6 | 0.39 | 0.4 | 0.31 | 0.20 |

| 双作用 | 6.4 | 5.0 | 2.8 | 3.3 | 2.13 | 2.71 | 1.75 | 1.11 | ||

| ZSQM | 单作用 | 公称压力 | ||||||||

| 双作用 | ||||||||||

| ZSQN | 单作用 | 0.89 | 0.57 | 0.35 | 0.56 | 0.36 | 0.45 | 0.30 | 0.20 | |

| 双作用 | 5.2 | 3.22 | 2.03 | 2.27 | 1.46 | 2.00 | 1.32 | 0.85 | ||

| 信号压力( KPa ) | 0 或 400~600 | |||||||||