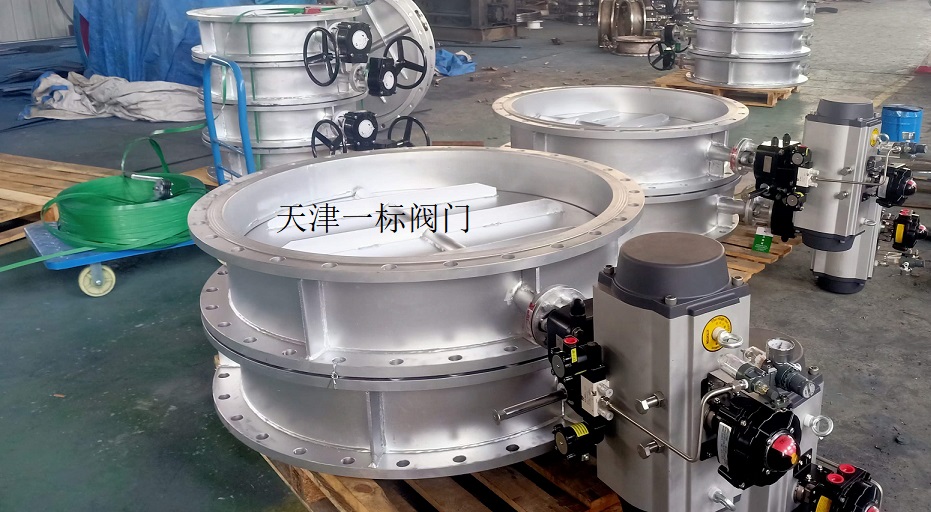

Pneumatic parallel double gate valve

Application of Pneumatic Parallel Double Gate Valve

Pneumatic parallel double gate valve has reliable performance, easy operation switching and maintenance, and has been widely used in various media control industries such as petroleum, chemical, and shipping

Characteristics of Pneumatic Parallel Double Gate Valve

1. Pneumatic parallel double gate valve equipped with pneumatic actuator and manual mechanism

2. The gate valve actuator adopts a double-layer cylinder structure, which doubles the lifting force compared to single cylinder pneumatic gate valves

3. Solved the problem of some valve plates of single cylinder pneumatic gate valves being wedged inside the valve body and unable to open

4. Equipped with a buffering mechanism, it can effectively reduce the wear of the valve plate sealing surface and valve body sealing surface caused by the downward impact of the piston when closing the valve, and also avoid the phenomenon of the gate plate getting stuck

【气动平行闸阀性能参数】

| 适用介质 | 适用温度(℃) | 材料 | ||||

| 阀体、阀盖 | 阀座、闸板及密封圈 | 阀杆 | 填料 | 气缸 | ||

| 水、蒸汽、油品等 | ≤350 | 碳素钢 | 堆焊铁基合金 | 铬不锈钢 | 柔性石墨 | 无缝钢管 |

The following is the core technical analysis of Z644H pneumatic parallel double gate valve, including comprehensive structural characteristics, performance advantages, and application specifications:

1、 Core structure and working principle

Dual cylinder actuator

Adopting a double-layer cylinder design, the thrust is doubled compared to a single cylinder, effectively avoiding the problem of gate jamming;

Built in buffer mechanism to reduce sealing surface wear caused by piston impact during closure;

Standard manual switching device (opening and closing nut engagement screw), supporting manual operation in case of gas source failure.

Bidirectional sealing design

Elastic pre tightening+floating valve seat: The spring pre tightening force combined with the medium pressure pushes the valve seat tightly against the gate, achieving zero leakage in both inlet and outlet directions (ANSI Class VI);

Self cleaning function: During the lifting process of the gate, spin is generated, grinding the sealing surface and removing impurities (especially suitable for dust media).

Wear resistant strengthening technology

The sealing surface adopts hard alloy welding or ceramic coating (such as WC Co wear-resistant layer), which increases the service life by 3-7 times;

The valve chamber is equipped with a blowing device (such as blowing the pipeline and sealing ring) to prevent ash accumulation and blockage.

气动闸阀 1.6MPa 主要连接尺寸

| 尺寸 | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | mm | 130 | 150 | 160 | 180 | 200 | 250 | 265 | 280 | 300 | 325 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 800 |

| H | mm | 175 | 180 | 210 | 210 | 350 | 358 | 373 | 435 | 500 | 614 | 674 | 818 | 1225 | 1415 | 1630 | 1780 | 2050 | 2181 | 2599 |

| W | mm | 180 | 180 | 200 | 200 | 200 | 240 | 240 | 280 | 320 | 360 | 360 | 400 | 450 | 500 | 500 | 600 | 720 | 720 | 720 |

气动闸阀 2.5MPa 主要连接尺寸

| 尺寸 | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | mm | 130 | 150 | 160 | 180 | 200 | 250 | 265 | 280 | 300 | 325 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 800 |

| H | mm | 175 | 180 | 210 | 210 | 350 | 358 | 373 | 435 | 500 | 614 | 674 | 818 | 1225 | 1415 | 1630 | 1780 | 2050 | 2181 | 2599 |

| W | mm | 180 | 180 | 200 | 200 | 200 | 240 | 240 | 280 | 320 | 360 | 360 | 400 | 450 | 500 | 500 | 600 | 720 | 720 | 720 |