Product

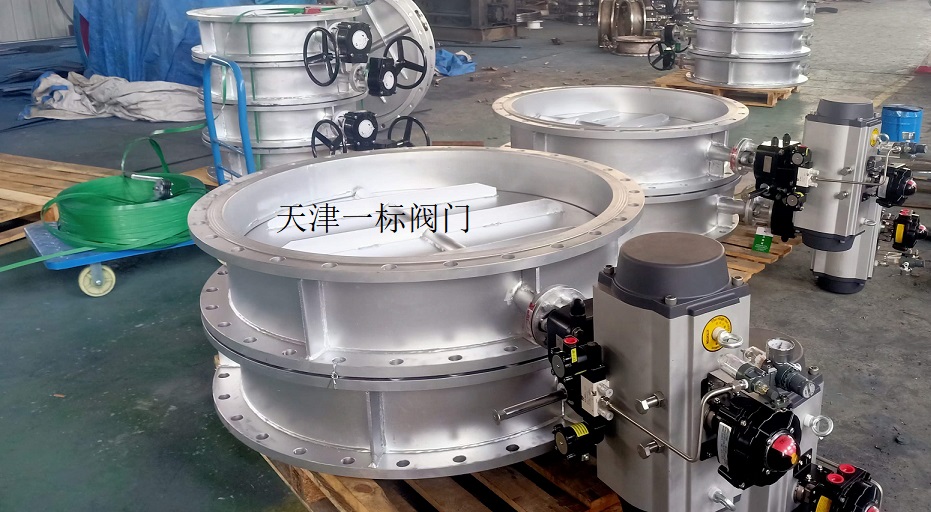

Pneumatic three-way butterfly valve

Brand:Pneumatic eccentric butterfly valve

气动三通蝶阀 is a three-way control device that combines butterfly valve structure and pneumatic actuator, mainly used for fluid switching and regulation in the field of industrial automation. The core features and application overview are as follows:1、 Structure type

Channel form

Similar to the structural differences of three-way ball valves, they may be divided into L-shaped and T-shaped:

L-type: achieve right angle switching of medium flow direction (such as connecting two vertical channels)

T-shaped: Supports flexible interconnection of three channels or individual closure of any channel

2、 Core Design

Control system

Adopting a dual solenoid valve and parallel cylinder design, coordinated control is achieved through the first and second gas supply branches. Even in the event of a power outage, production can still be quickly restored through manual paddles or spring reset mechanisms.

Executing Agency

Usually equipped with double acting or single acting pneumatic devices, the driving air source pressure range is 5-7 bar, and supports accessory expansion functions such as locators and limit switches.

3、 Technical advantages

Low voltage loss regulation

Butterfly valves can achieve sensitive flow control within the opening range of 15 °~70 °, and have low flow resistance when fully opened, making them suitable for large-diameter pipeline scenarios.

Emergency reliability

The dual cylinder and redundant air circuit design effectively avoid production interruptions caused by single solenoid valve failures, ensuring system stability.

Medium resistance characteristics

Butterfly movement has a self-cleaning effect and can be adapted to working conditions containing suspended particles or powdered media, depending on the sealing material (such as EPDM, PTFE) selected.

4、 Typical applications

Industrial automation: used for flow switching in material conveying systems and fluid distribution in production lines.

Pipe network regulation: achieving hydraulic balance in water treatment or heating systems to eliminate the problem of uneven heating and cooling.

Corrosive media: UPVC and CPVC valve bodies can withstand acid, alkali, and chemical fluids, commonly found in the food and semiconductor industries.

Technical Specifications

Valve body: ASTM A536 65-45-12, WCB, CF8M, UPVC, etc

Valve plate: ASTM A536 65-45-12, nylon coating, CF8, CF8M, UPVC, etc

Valve seat: EPDM, NBR, FRM, PTFE

Valve stem: SS420, SS431, 17-PH4

Valve body styles: clamp type, LT lug type, flange type

Nominal diameter: 2 "-80" (DN50mm - DN2000mm)

Flange adaptation: DIN PN10 PN16, JIS 5K 10K, ANSI CLASSS 150LB

Pneumatic actuator: double acting, single acting

Electric actuators: ON-OFF type, adjustable type, explosion-proof, etc

【Bace】