Product

Pneumatic gate valve _ Pneumatic knife gate valve

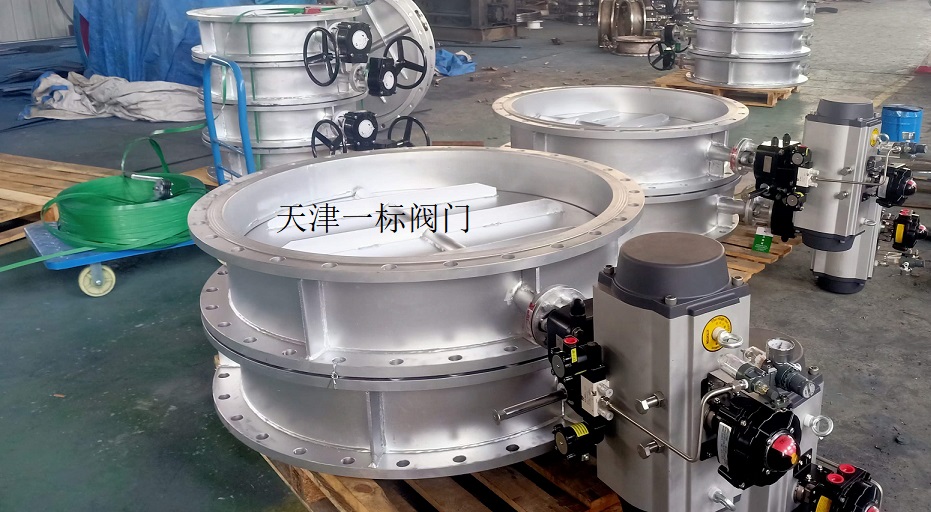

Brand:Pneumatic eccentric butterfly valve 型号:Z641H-16

Comparative analysis of pneumatic gate valve and pneumatic knife gate valve:

1、 Core structure and working principle

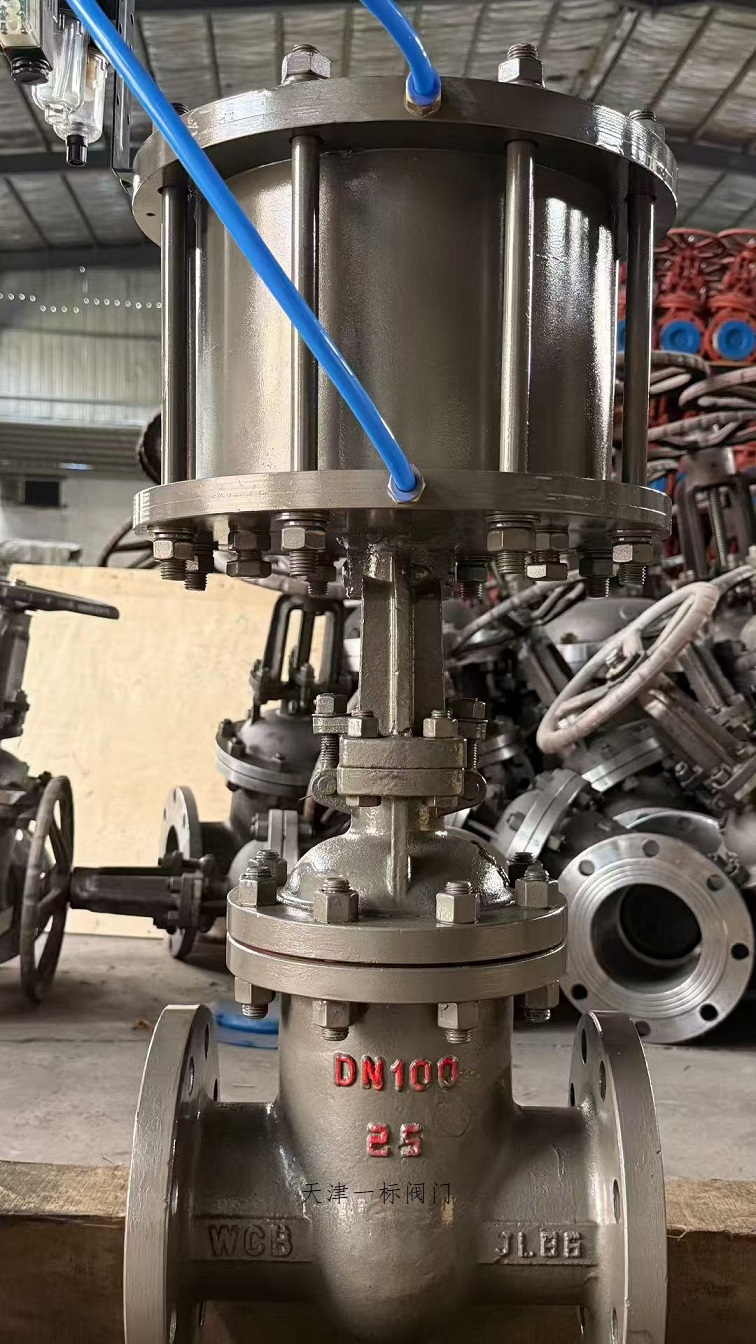

Pneumatic gate valve

Adopting gate vertical motion control for medium on/off, with a flat or wedge-shaped sealing surface design, suitable for fully open/fully closed working conditions.

Typical structure: visible stem type (valve stem lifting visible) or concealed stem type (valve stem not lifting).

Pneumatic knife gate valve

The gate is in the shape of a blade and is driven up and down by a pneumatic actuator. It has a shearing function and can handle media containing particles.

Typical structure: For clamp or flange connections, the sealing surface is either a soft seal (rubber/PTFE) or a hard seal (metal/ceramic).

2、 Performance comparison

Parameter Pneumatic Gate Valve Pneumatic Knife Gate Valve

Sealing grade ANSI Class IV~VI ANSI Class VI (soft seal)

Applicable pressure PN1.0~PN25 PN1.0~PN16

Applicable temperature -40 ℃~550 ℃ -40 ℃~200 ℃

High flow resistance coefficient (when the gate is fully open) and extremely low (blade shaped flow channel design)

Advantage scenario:

Pneumatic gate valve: High pressure cut-off for cleaning media such as high-pressure steam and oil.

Pneumatic knife gate valve: wear-resistant control for media containing solid particles such as slurry and sewage.

3、 Typical application areas

Petrochemical industry

Pneumatic gate valve: High pressure cut-off of crude oil pipelines (as per API 6A standard).

Pneumatic knife gate valve: control of catalyst particle transportation.

Environmental Protection Engineering

Pneumatic knife gate valve: Sludge discharge from sewage treatment plants (such as PZ673X-10C model).

Metallurgical industry

Pneumatic gate valve: High temperature gas pipeline (such as Z941H-16C hard seal gate valve).

选型建议

【Bace】