Product

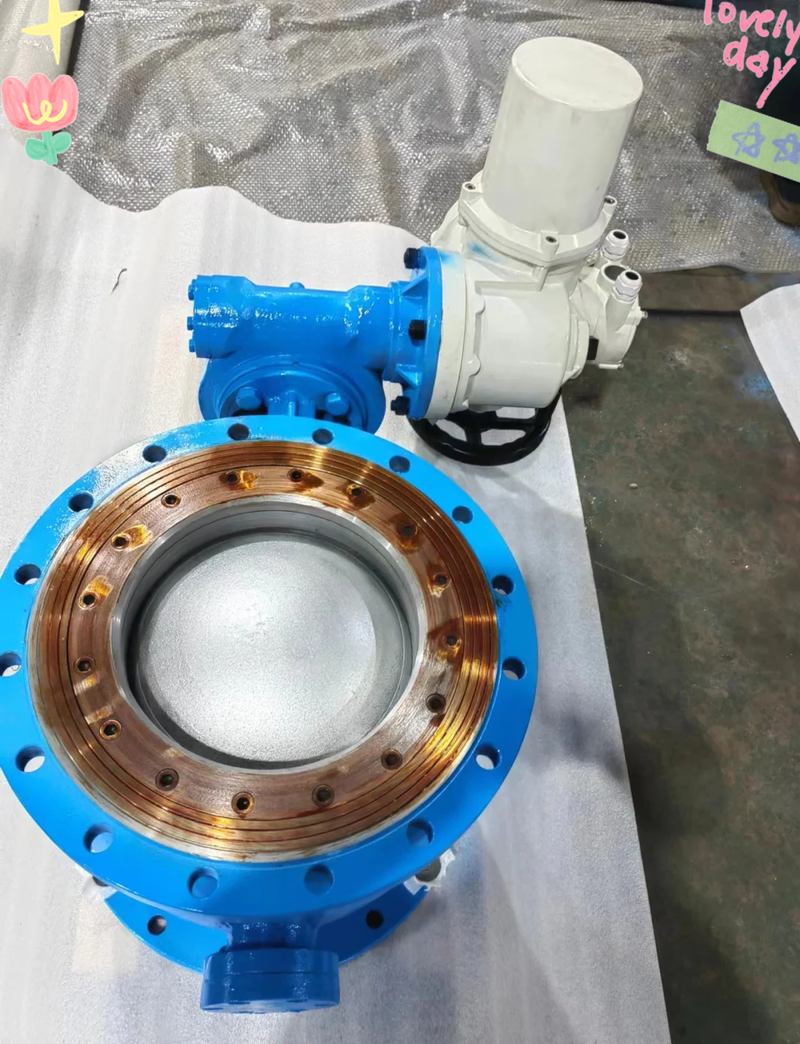

Upper horizontal axis eccentric hemispherical valve

Brand:Pneumatic eccentric butterfly valve

上装卧轴偏心半球阀Integrating the advantages of convenient maintenance and stable horizontal axis structure, the horizontal valve shaft installation reduces the height of the valve body and minimizes the space occupation of the flow channel. The sealing surface is precise and adjustable, and the core components of the valve do not need to be disassembled as a whole for maintenance. The top cover can be opened for operation, greatly simplifying the process. Whether it is in the chemical, power, or water treatment industries, it can accurately control the flow and ensure the stable operation of the system.上装卧轴偏心半球阀It is a valve designed specifically for harsh working conditions in industrial pipelines. Its core advantages lie in its double eccentric structure, upper mounted maintenance, and horizontal axis installation form, which can effectively solve the problems of traditional valves such as easy wear and maintenance difficulties. The main features are as follows:

1、 Core Structure and Technical Principles

Double eccentric design: There is a specific offset between the valve shaft and the center line of the ball, and the ball crown disengages from the valve seat at the moment of opening and closing, avoiding rotational friction. When closed, it relies on the principle of eccentricity to achieve bidirectional sealing (the ball presses the valve seat tightly under positive pressure, and the floating valve seat automatically compensates under negative pressure).

Horizontal shaft layout: The valve shaft is installed horizontally, combined with a flat bottomed flow channel design, significantly reducing flow resistance (almost zero pressure loss when fully open), suitable for high flow pump stations and sediment erosion scenarios.

Top mounted maintenance: The valve cover is detachable, and internal parts (such as the ball crown and valve seat) can be directly lifted out from the top for online replacement without disassembling the pipeline.

2、 Performance advantages

Wear and corrosion resistance:

The sealing pair adopts bimetallic surfacing technology (such as alloy nitriding steel), and surface hardening treatment improves wear resistance.

When the sphere rotates 90 °, the medium uniformly flushes the flow channel 360 °, automatically cleaning scaling and impurities.

Long lifespan and easy maintenance:

Reserve compensation for the sealing surface, restore the seal by adjusting the compression nut after wear, and support separate replacement of the valve seat.

Hydraulic or electric drive achieves millisecond level response, suitable for automation control.

3、 Typical application scenarios

Scope of applicable medium specifications in the field

Energy crude oil, natural gas, coal powder and ash DN40-DN1600

Chemical containing granular slurry and crystallization solution

Municipal sewage treatment, heating and heating

Electric and hydraulic slag removal, gas ash transportation pipeline

4、 Industry Progress

By 2025, the third generation of flat bottomed horizontal shafts will have achieved mass production, supporting larger diameters (such as DN1500+) and high-temperature conditions (-50 ℃ to 600 ℃). Representative enterprises such as Tianjin Yibiao Valve have received high praise for their products in the fields of coal chemical industry and long-distance pipelines.

Note: When selecting, attention should be paid to the sealing material (such as corrosion-resistant alloy welding) and driving mode (manual/pneumatic/electric) to adapt to specific medium characteristics and automation requirements.

【Bace】