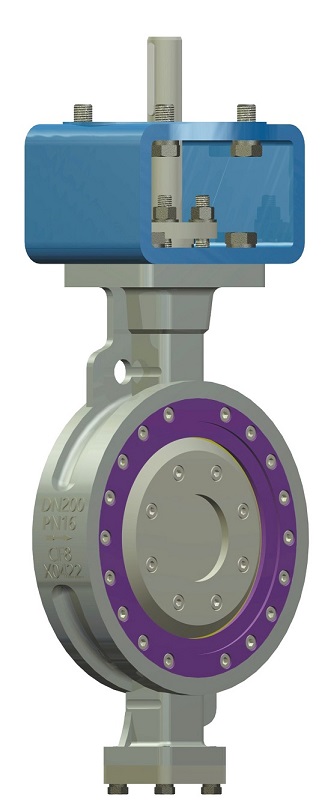

Four eccentric butterfly valve

四偏心蝶阀is a high-performance valve further optimized on the basis of a three eccentric butterfly valve. By adding a fourth eccentric structure (eccentric sealing section shape), it significantly improves sealing performance, flow efficiency, and durability, especially suitable for harsh working conditions with high pressure, high temperature, and high cleanliness requirements.

Its core features and technological advantages are as follows:

Structural principle

Four eccentric design

Radial eccentricity: The axis of the valve plate deviates from the center of the pipeline, eliminating radial friction.

Axial eccentricity: The sealing surface is placed on one side of the valve stem to reduce opening and closing resistance.

Angle eccentricity: The conical axis of the sealing surface forms an angle with the axis of the valve body, achieving line contact sealing.

Eccentricity of cross-sectional shape: The sealing ring has been optimized from an ellipse to a perfectly circular shape, increasing the flow cross-section and reducing the unbalanced force of the medium on the valve plate.

When closed, the curvature of the valve plate perfectly matches the flow channel, and the medium pressure pushes the sealing surface to self lock, achieving zero friction opening and closing.

Sealing technology upgrade

Self reinforced sealing: relying on the pressure of the medium to automatically press the sealing surface tightly, the sealing effect increases with the increase of pressure.

Metal hard seal: The valve seat is welded with corrosion-resistant alloy (such as Stellite alloy), which can withstand extreme temperatures from -196 ℃ to 850 ℃.

Special process application: High end models use nano coated valve bodies, magnetic fluid seals or magnetic levitation drives to achieve ultra-high cleanliness standards (such as reducing particle pollution in semiconductor production lines by 99%).

Performance advantages

Characteristics: Traditional three eccentric butterfly valve and four eccentric butterfly valve

Flow capacity with elliptical cross-section and high resistance with a perfectly circular cross-section, resulting in a 15% -20% increase in flow rate

Sealing reliability position sealing, relying on elastic deformation torque sealing, contact surface pressure adaptive medium pressure

Suitable for high pressure differential conditions (such as PN40 or above) and stable sealing in medium and low pressure scenarios with bidirectional pressure bearing capacity

During the initial stage of wear control opening and closing, there is slight scratching and no contact throughout the entire process, which extends the service life by more than 50%

Typical application scenarios

High temperature and high pressure media: such as high-temperature flue gas from power plants (≤ 550 ℃) and chemical alkali pipelines.

High cleanliness environment: semiconductor production lines, nuclear facilities (with a leakage rate compliance rate of 100%).

Frequent opening and closing conditions: Due to extremely low wear rate, it is suitable for systems that require thousands of operations per day.

Comparison of Technological Evolution

Single/Double Eccentricity: Only solves the extrusion problem, there is still scratching, suitable for low pressure and room temperature.

Triple eccentricity: achieving metal sealing, but with limited flow cross-section.

Four eccentricities: comprehensively eliminating friction, optimizing flow channels, and enhancing sealing, representing the highest technological level of butterfly valves currently available.

Tip: When selecting, attention should be paid to the valve body material (such as CF8M corrosion-resistant alloy) and driving method (magnetic levitation driving can reduce particle release).

选型建议