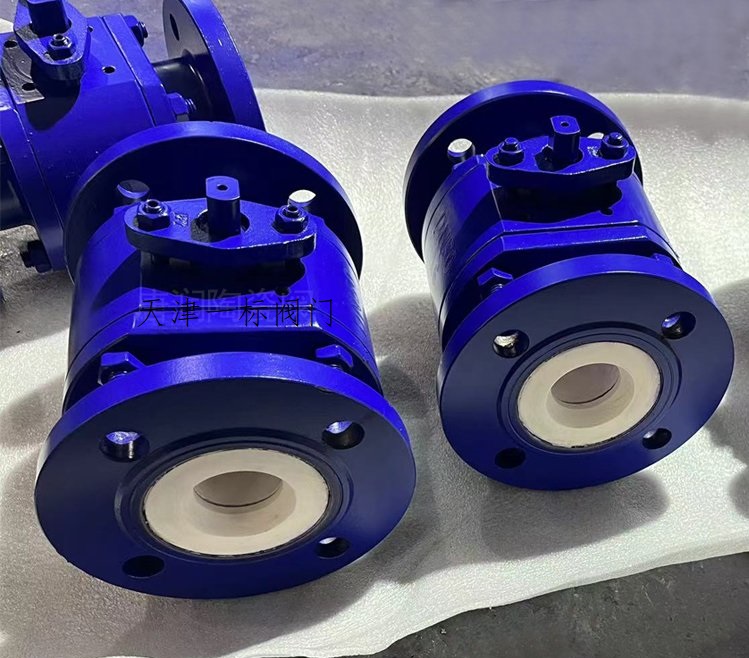

Ceramic ball valve

1、 Product Overview

Ceramic ball valves use ceramic materials such as alumina and silicon carbide as core components, and all contact surfaces with the medium are made of structural ceramics with Rockwell hardness HRC90. They have strong chemical stability and excellent sealing performance. Its design solves the problems of leakage, high torque, and non corrosion resistance of traditional metal valves, especially suitable for harsh working conditions such as desulfurization slurry, dust, and highly corrosive media.

2、 Technical parameters

Nominal pressure: 0.6~10MPa (some high-pressure models can reach PN64).

Applicable temperature: -40 ℃~500 ℃ (special design can reach over 1000 ℃).

Drive mode: manual, pneumatic, electric (such as PZ941TC model).

Diameter range: DN15~DN1000 (customizable).

3、 Core Features

Wear resistant and corrosion-resistant: Ceramic materials have a hardness second only to diamond, and their wear resistance is 2-4 times that of metal valves.

Sealing performance: The sphere is precisely ground and aligned with the valve seat to achieve zero leakage through ceramic self-lubricating properties.

Structural optimization: three-stage thickened shell, nitrogen treated valve stem, and buffer compensation elastic gasket design.

选型建议