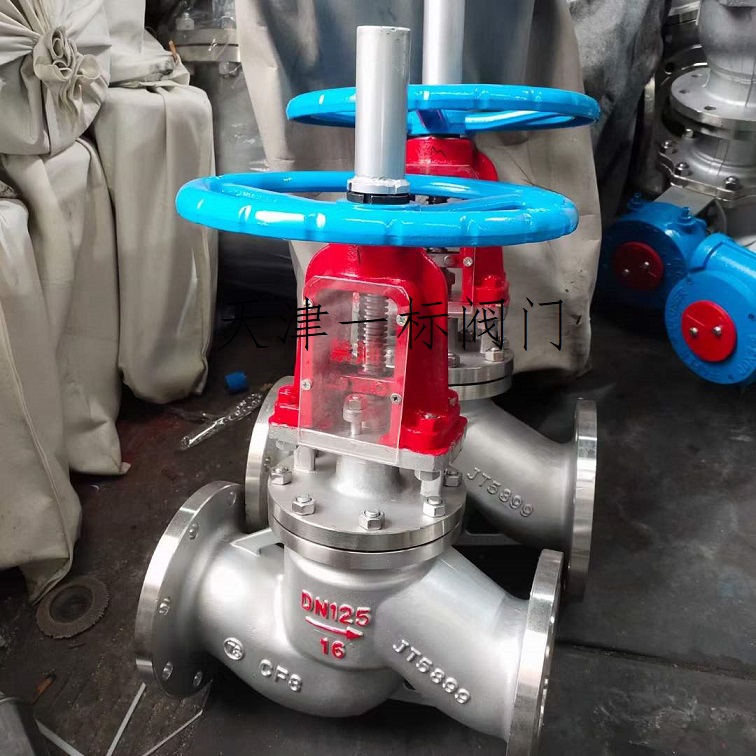

Oxygen shut-off valve

1、 Definition and Function

Oxygen cut-off valve is a forced sealing valve specifically designed for oxygen pipeline systems. It is controlled to open and close by the lifting and lowering of the valve stem and is suitable for non corrosive gas media such as oxygen, nitrogen, and hydrogen. Its core functions include:

Safe interception: prevent medium backflow and ensure the sealing of the pipeline system.

Explosion proof design: Adopting oil free degreasing process to avoid the risk of combustion and explosion caused by contact between oil and oxygen.

2、 Technical features and structure

Sealing and Material

Sealing surface: Nylon or polytetrafluoroethylene (PTFE) soft seal, some models use Babbitt alloy hard seal.

Valve body material: stainless steel (such as 304/316) or flame-retardant copper alloy, and non flammable lubricating grease is used for the valve stem transmission part.

Structural form

Straight through type: high fluid resistance, suitable for conventional working conditions.

DC type: low flow resistance, suitable for high viscosity media.

Angle type: commonly used for pipelines with limited space (such as laboratory equipment).

Operational requirements

When the opening height is 25% -30% of the nominal diameter, it reaches the fully open state.

During installation, the valve stem should be kept vertically upward and contact with oil is strictly prohibited.

选型建议