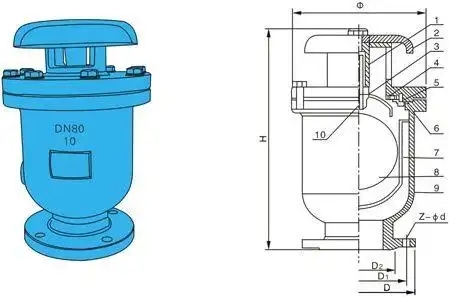

Intelligent air valve

智能空气阀is a high parameter air valve used in smart water delivery systems. The valve has the characteristics of automatic intake and exhaust, continuous micro exhaust, secondary high-pressure exhaust, damping exhaust, etc. It can solve the problems of air resistance, negative pressure, water hammer, two-phase flow, etc. in water delivery systems. At the same time, the valve is designed with a dedicated sensing interface and a multi-channel control system. Through the control module loaded on the valve, real-time information such as valve pressure, liquid level, leakage, and opening stroke is collected and uploaded to the platform in real time. The multi-channel control system can remotely control the air valve and actively exhaust when necessary.

智能空气阀feature

1. The valve has a complete built-in online detection system, which comprehensively detects the real-time information of the air valve and its nodes, including real-time pressure, liquid level, leakage information, valve opening information, etc. It can be directly connected to the intelligent water supply system platform to provide real-time dynamic information of the pipeline for the system.

2. The exhaust port is divided into three sections and adopts a differential control structure. According to the working period of the water supply system, it meets the functions of large exhaust volume, high pressure exhaust volume, two-phase flow restart exhaust, and damping exhaust when the water column is closed.

3. The overall built-in micro exhaust port adopts a conical ring roller shutter structure, with a large micro exhaust port, far exceeding the standard requirements. At the same time, when a larger pressurized exhaust capacity is needed, the system can switch to a larger pressurized exhaust port at the appropriate time based on real-time data detected, completely solving any air resistance problems during system operation.

4. The control module has relay functions such as real-time detection of valve parameters, wireless remote transmission of real-time uploaded information, and sending system commands to control valve exhaust port switching.

建议